WING-MAX 8 to 16 Row Planter

Strong Construction

The WING-MAX planter can be configured as a thoroughbred No-Till planter or as a conventional machine thanks to the double beam construction that spans right across the full width of the planter. Two beams make a stronger hinge, and such strength is needed when your choices of fertiliser tool include the popular Monosem No-Till coulter and trip tine.

But the double beam design doesn’t just add strength to the construction, it also adds the space for any other fertiliser tool in the Monosem range including the 20” single disc opener. You don’t need to change the way you apply fertiliser after you bought a Monosem WING-MAX planter. Whatever fertiliser tool you are used to, Monosem will have an equivalent to fit onto the WING-MAX planter. There is more than enough strength and space on a WING-MAX to fit the fertiliser tool you like most.

Excellent visibility and maneuverability

The WING-MAX provides excellent visibility with the planter bar in front of the fertiliser tank. Maneuverability is also improved with this design coupled with the lift linkage, the planter bar is closer to the tractor, headland management is also improved at the same time when turning around and positioning the planter in some spots

Wing-Max vertical fold planter positions :

WING-MAX in transporting position

Quick and easy

The vertical fold WING-MAX planter is quick and easy to fold and unfold. You don’t need to leave the tractor cab to get the planter from transport to planting position and from planting to transport position. Locking the wing sections for planting and un-locking them before fold-up is part of the hydraulic sequence. When the extending folding cylinders reach the end of their stroke after fully unfolding, the wing sections are already locked in planting position. But as soon as these folding cylinders start to retract, the wing sections are unlocked automatically. While transporting it from field to field, the WING-MAX is stable and a pleasure to pull around.

WING-MAX in planting position

Floating beam sections enable planting over uneven terrain.

The wing sections of the WING-MAX can float 12 degrees up and 12 degrees down during planting. Three row-units on either side of a 12-row and four row-units on a 16-row WING-MAX planter are mounted on a separate beam section that pivots around a low hinge point connecting it with the centre section of the frame. The low hinge point ensures that row spacing variation is kept to a minimum over the hinge. A ground wheel guides each of the outer beam sections so that they keep consistent ground clearance, even over hilly terrain. A hydraulic cylinder puts pressure on those floating wing section, transferring weight from the heavier centre section to the lighter wing section of the WING-MAX planter to ensure each row-unit and fertiliser tool can apply the same down force no matter where it is positioned. This hydraulic weight transfer and the low hinge point make the WING-MAX an ideal planter for uneven terrains. Ground contours that push the wing section upwards during planting will not work against the floating cylinder but against the set pressure of the weight transfer cylinders.

Wing-Max in turning position

Easy turning due to gull-wing feature

The innovative hydraulic system of the WING-MAX raises the wings upward, 12 degrees with each turn on the headland. The tractor driver does not need to do it separately but the two weight transfer cylinders that put pressure on the wing sections during planting get retracted automatically after the planter is lifted so that the wing sections of the planter lift even further. Therefore, the Wing-Max planter requires less space to turn because the raised wings can overhang certain obstacles. In addition to the fact that the planter beam of the WING-MAX is positioned in front of the fertiliser cart, close to the tractor, this gull-wing feature reduces the need for headland planting.

Carrier Wheels

Large Trelleborg 480/80 R50 radial agricultural tires provide a large footprint

Weight Transfer

Equipped with weight transfer cylinders to help with weight distribution across the entire planter width

Row Cleaner Options

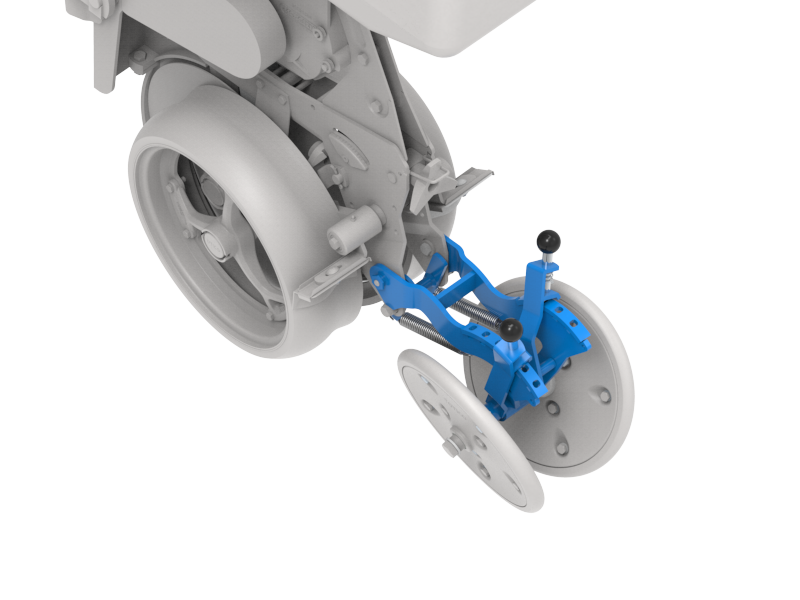

Adjustable Rear Wheel Bracket Options

Two Lever Bracket

adjustable toe-in, toe-out and downforce

Screw Bracket

adjustable downforce only

Closing Wheel Options

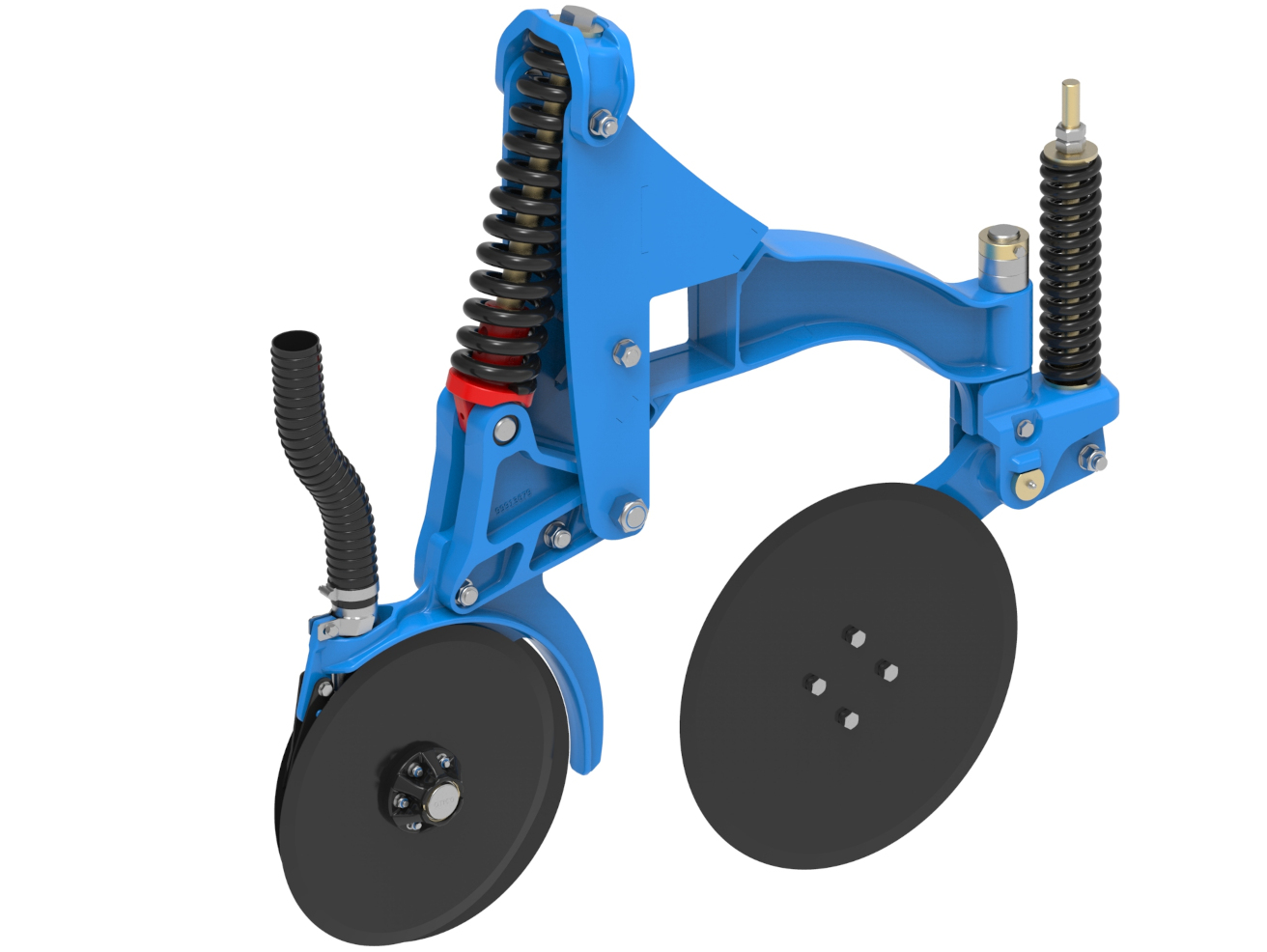

Conventional and No-Till configurations

510mm Fertiliser opener disk

Coulter and Tine

Coulter and Double disk

Dry Fertiliser Bins

5500 litre central fertiliser bin are made from a heavy duty polyethylene that is lightweight but still highly durable. The lightweight tanks allow for larger fertiliser loads to be used and effectively reduces down time due to refilling.

Most accurate dry fertiliser meter

- corkscrew auger handles poor quality fertiliser without fertiliser build-up

- brilliantly designed for even and consistent fertiliser output row by row

Pro Wheel Option

The press wheel has been used for years on the vegetable and sugar-beet planters. MONOSEM has adapted this concept to the multipurpose planters with a large diameter press wheel, the PRO wheel.

Consistent pressing ♦ Improved plant emergence ♦ Optimal germination ♦ Better seed placement quality

Large diameter press wheel

The PRO wheel in aluminium has a stainless steel coating and a plastic scraper. Wide diameter (295mm), it keeps its shape and offers a quality pressing and a better seed placement. By improving the seed-to-soil contact, the emergence is more rapid and regular.

Combined adjustment

The packing down pressure of the PRO wheel is adjustable. It is combined with the pressure adjustment of the rear packing unit (a).

Independent wheel

Independant from the planting system and the rear press unit, the PRO wheel follows the ground contours for a

consistent pressing.